Sonic Drilling

- Sonic Drilling offers an unrivalled production rate through overburden when compared to comparable techniques, including through hard and soft formations, cobbles, boulders, made ground etc. – reduced client and project overhead costs

- Sonic Drilling does not suffer from refusal upon encountering difficult to drill material – builds confidence in upfront supply chain cost projections

- Quality continuous soil profiling offered as standard

- Most in-situ geotechnical samplers/apparatus easily incorporated between drill runs

- Option to utilise rigs for conventional rotary coring including triple tube rotary coring thus offering huge degree of flexibility when drilling and sampling

- The technique is inherently clean producing only minimal drilling derived waste products – ideal for sensitive environmental sites and the nuclear environment where Sonic Drilling offers one of the very few solutions to drill safely

Basic Procedure

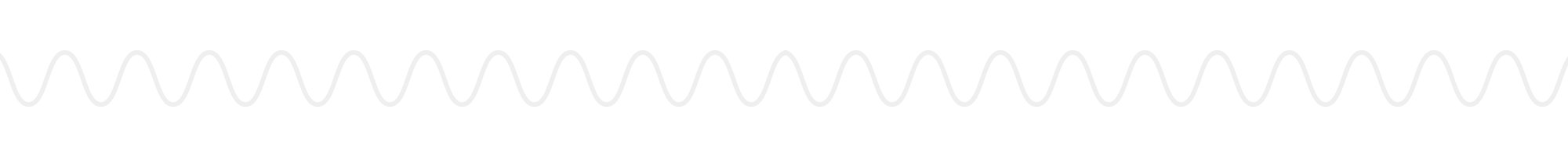

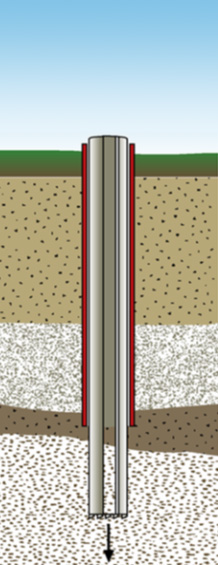

Step 1:

Core Barrel Advancement

No fluids, air or mud used during coring

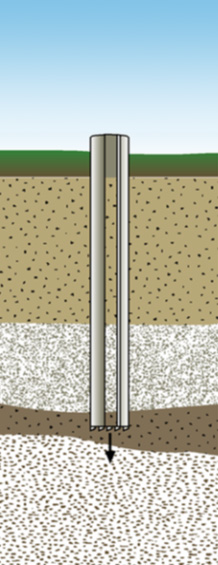

Step 2:

Casing Override

Water used between casings possibly – formation dependant

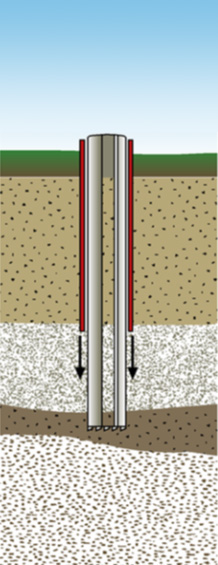

Step 3:

Retrieve Core Barrel for Sample Extrusion

Step 4:

Repeat Core Advancement Following Sample Extrusion

Samples

GeoSonic’s Sonic rigs can offer continuous soil samples (presented in either flexible plastic liner bag or semi-rigid plastic liners) recovered by means of Sonic Drilling.

A full range of geotechnical samples can also be recovered by means of dedicated geotechnical samplers utilising the same rig but without the use of resonance. These include thin walled samplers, piston samplers etc. which meet the requirements of current Eurocode standards.

Full details of our capabilities are listed in the Services & Experience section.